New Products | Dadi Group Meiteng Technology

Safer to use, Easier to manage

High Precision and Fast On-line Detection

Real-time adjustment of sorting density and parameters

The X-ray ash analyzer developed by Tianjin Meitong Technology Co., Ltd., a member of Dadi Engineering Development Group, realizes on-line detection of coal ash by using X-ray transmission principle, and meets the demand of coal ash detection in coal mines, coal preparation plants and coking plants. Compared with γ ray ash analyzer, X ray ash analyzer has higher detection accuracy and shorter detection period, and simpler management and use.

1. Wide application

It can be widely used in coal ash detection in coal mines, coal washing plants, coking plants, coal blending plants, coal-fired power plants, iron and steel plants and coal terminals.

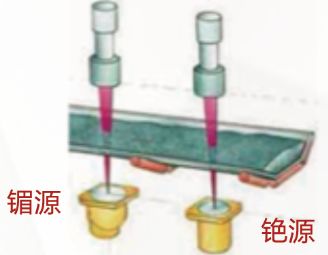

2. Working Principle

The X-ray ash analyzer establishes a relationship model between the ray intensity of the X-rays passing through the coal stream and the ash of the coal stream, and realizes online detection of coal ash by real-time calculation.

3. Main Technical Indicators

Detection accuracy (absolute error)

When the ash content is<15%, ≤0.5%, 1σ;

When the ash is 15-30%, ≤1.0%, 1σ;

When ash is >30%, ≤1.5%, 1σ.

4. Product Performance and Operational Environment

Quality stability: Continuous measurement of 8h standard test block, the maximum deviation between any “10min ash” measurement value and the average value does not exceed ±0.5%.

Output content: instantaneous ash/shift average ash/accumulative ash since start-up /real-time adjustment guidance. If an intelligent close control system is built, density adjustment parameters can be provided; if a coal blending system is built, coal blending adjustment parameters can be provided.

Storage cycle: one year

Moisture effect: The moisture change is ±1%, and the ash measurement changes by about ±0.1%.

Intelligent: Through Industrial Ethernet access to the “TCPB Intelligent Coal Preparation Brain” system developed by Meitong Technologies of Dadi Group, the separation density and parameters can be directly adjusted.

Belt speed and coal sample thickness requirements:

The belt speed is below 5m/s, and the continuous thickness of the coal seam on the conveyor belt is above 50mm.

Ambient temperature and relative humidity:

Adapt to the environment -10 ° C ~ 40 ° C, relative humidity of 85% or less.

5. Product Advantage

The X-ray ash analyzer is a type III X-ray device of the same type as the safety analyzer. It is a kind of X-ray device with the least harm to human health and the environment, so it has high safety.

The X-ray ash meter uses a leaded shield for safe operation.

No radiation is generated after power cut-off, therefore, maintenance is safer.

The management is simpler. The X-ray device is an electronic device (non-radioactive source). It only needs to be filed by the municipal environmental protection bureau for verification and use.

The X-ray ash analyzer is fan-shaped detection, which is wider than single point detection. It has strong sample representativeness and higher detection accuracy.

6. Interface Display

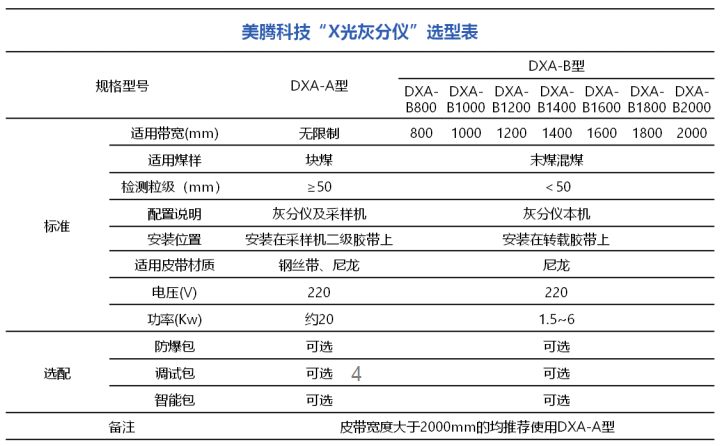

7. Equipment Selection

Tianjin Mei Teng Technology Co., Ltd.

Dadi Engineering Development Group