-

Introduction to Entrusted Operation Business

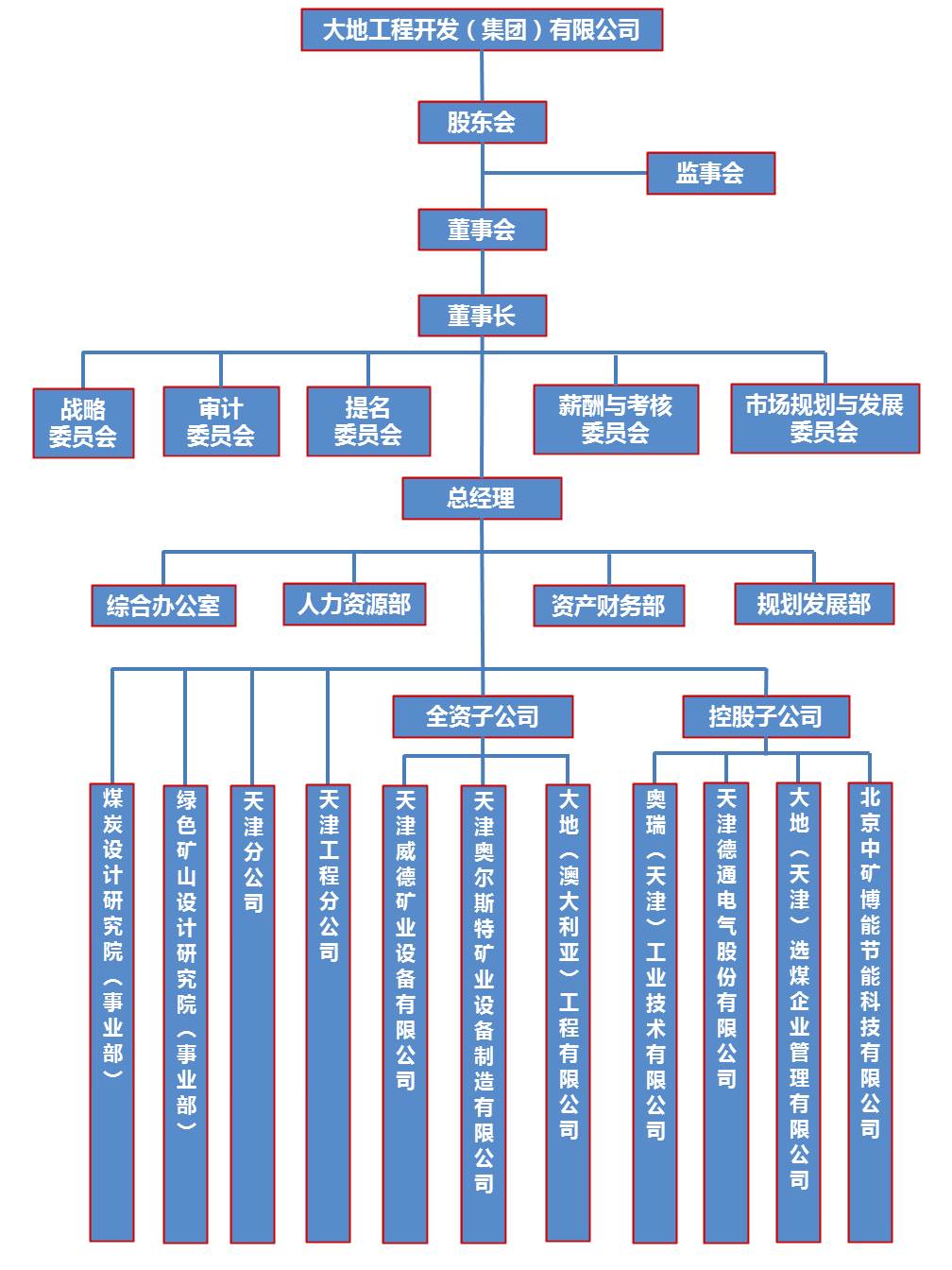

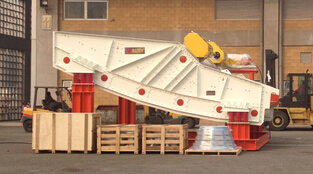

The Dadi (Tianjin) Coal Preparation Enterprise Management Co., Ltd. of Dadi Group is a professional enterprise engaged in the operation and commissioning of coal preparation plant. At present, more than 20 coal preparation plants are contracted and operated, with annual coal washing capacity of more than 100 million tons, and the products sell well both at home and abroad.

-

1. Liangshuijing Coal Preparation Plant, Shaanxi Shenmu Huisen Liangshuijing Mining Co., Ltd. (7 Mt/a)

All raw coal is washed in the washing process, 200-30mm is separated by heavy medium shallow separator, 30-1.5mm is separated by two-product heavy medium cyclone, 1.5-0.1mm is separated by spiral separator, slime less than 0.1mm is concentrated by thickener and recovered by press filter, and the production system adopts single system.

-

2. Gaotouyao Coal Mine Coal Preparation Plant of Inner Mongolia Beiliandian Energy Development Co., Ltd. (10 Mt/a)

Washing process uses 150-13mm lump coal dense medium separator to discharge waste; 3-0.1mm coarse slime is recovered by slime centrifuge, fine slime is filtered by pressure, and the production system adopts double system.

-

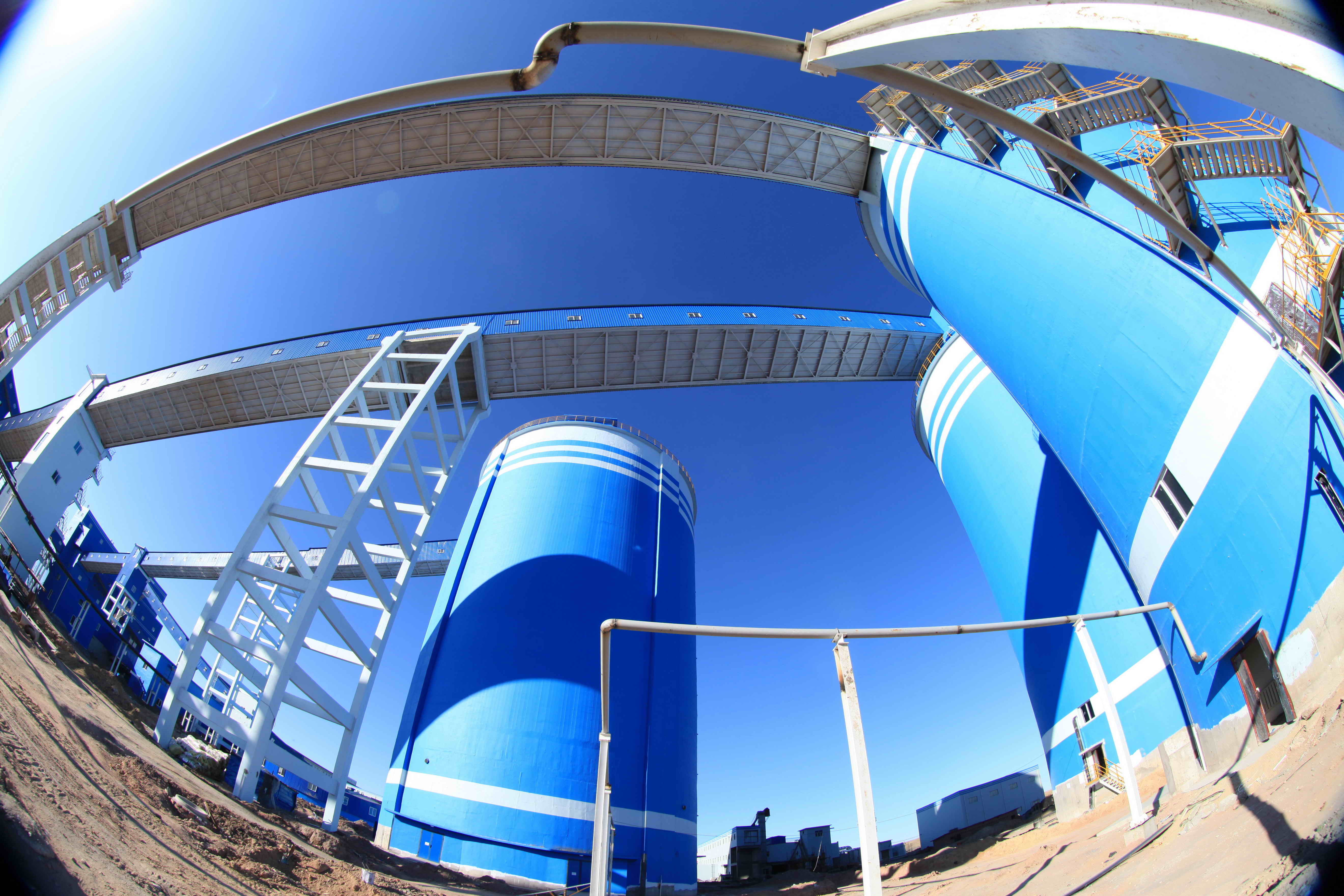

3.Chahasu Mine Coal Preparation Plant (15 Mt/a) of Guodian Jiantou Inner Mongolia Energy Co., Ltd.

The washing process adopts the washing method of 200-25mm lump coal dense medium shallow separator, no washing of final coal and recovery of pressure filter after coal slime concentration, reserving the possibility of 25-1.5mm dense medium cyclone separation for final coal and 1.5-0.25mm spiral separation for coarse slime.

-

4. Huangyuchuan Coal Preparation Plant of Shenhua Shendong Coal Group Co. (15 Mt/a)

Located in Gaotouyao Village, Zhaojun Town, Dalat Banner, Ordos City, Inner Mongolia, it belongs to Inner Mongolia Beiliandian Energy Development Co., Ltd. It is a underground coal mine thermal coal preparation plant with capacity of 10.0Mt/a thermal coal. Washing process uses heavy medium shallow separator for waste discharging of lump coal, centrifugal recovery of coarse slime and pressure filtration recovery of fine slime.

-

5. Wangjialing Coal Preparation Plant of Wangjialing Coal Industry Co., Ltd. of Shanxi Coal Transportation and Sales Group (6 Mt/a)

In the washing process, 200-13(25) mm lump coal is separated by heavy medium shallow separator; 13(25)-1.5mm final coal is separated by two-product pressure dense medium cyclone; 1.5-0.15 mm coarse coal is separated by spiral separator; 0.15-0 mm fine coal is recovered by pressure filter and pressure filter.